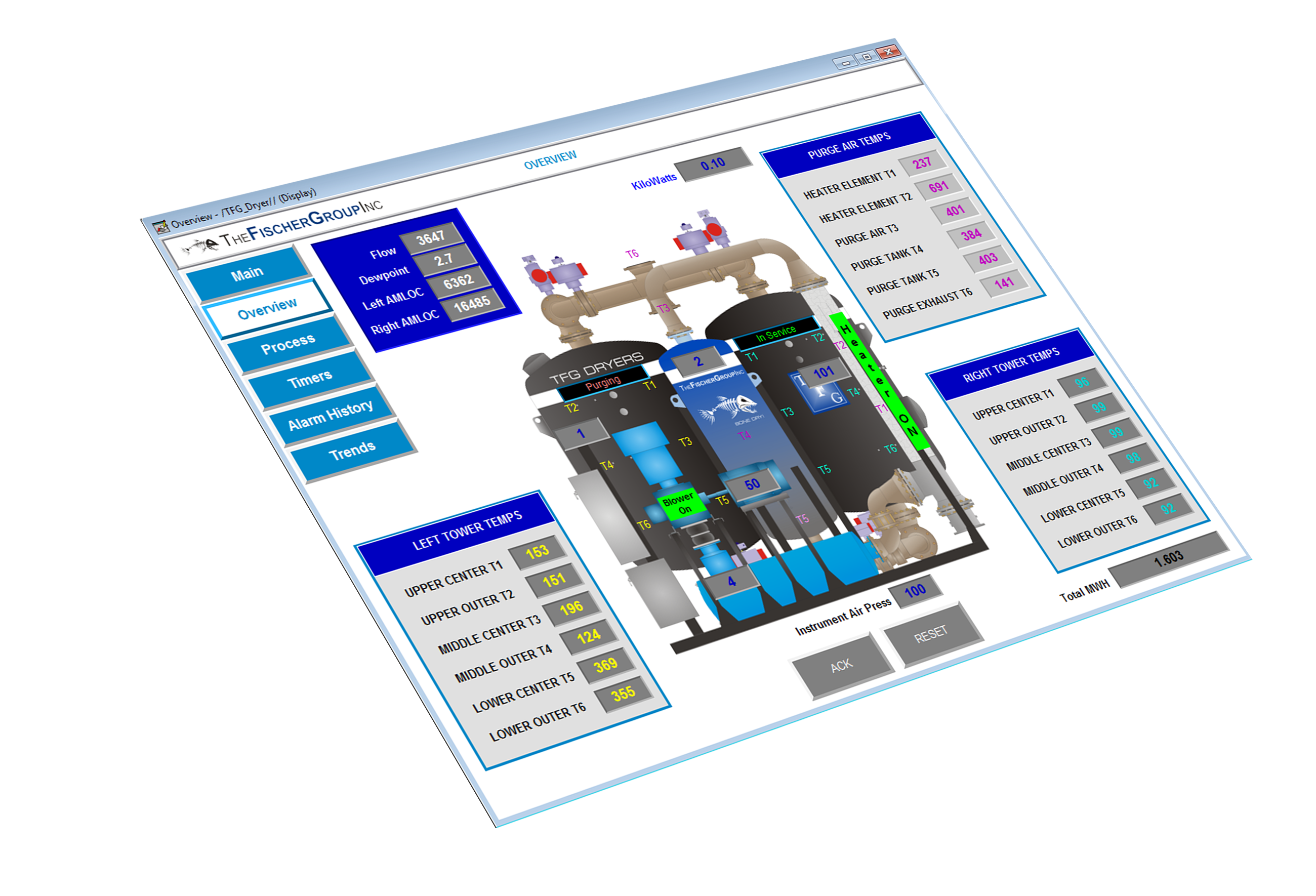

Smart control algorithms match system and atmospheric conditions to control the dryer.

VFD and multi-circuited heaters with energy smart algorithms maximize energy efficiency.

Modular system construction saves installation costs and simplifies maintenance.

The purge air will be dried during the cooling cycle, eliminating the waste of plant air.

No other dryer in the market can match the efficiency of the TFG Bone Dry™ Desiccant Dryer.

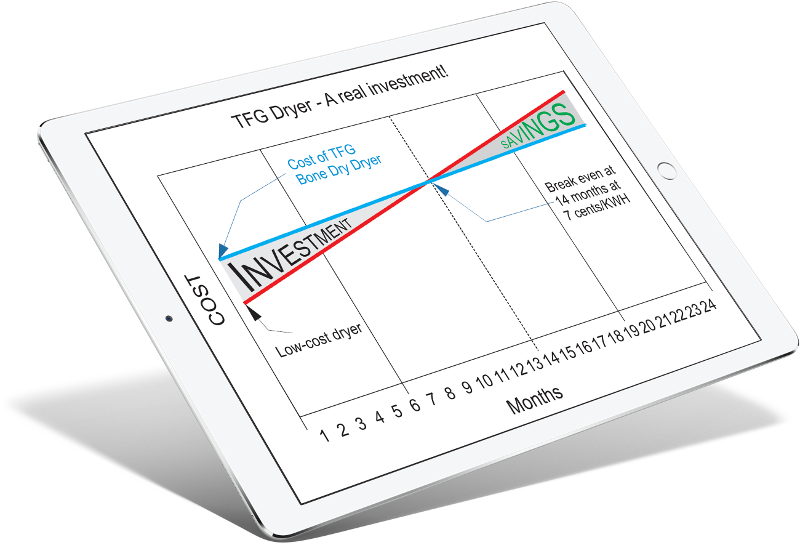

The TFG Dryer is an investment that would eliminate the use of plant air for regeneration.

TFG Dryers deliver pre-treated air to the desiccant bed during the regeneration cycle, extending its the life while saving energy.

| Modular | Simplifies installation and maintenance. |

| Configurable | Footprint is adjustable to fit your floor space. |

| Advanced | Air Distribution and Barrier System improve desiccant utilization. |

| Responsive | Environmental controls protect desiccant from overheating, saving energy and increasing desiccant life. |

Bone Dry Dryers do not waste plant air for sweeping, cooling, or stripping.

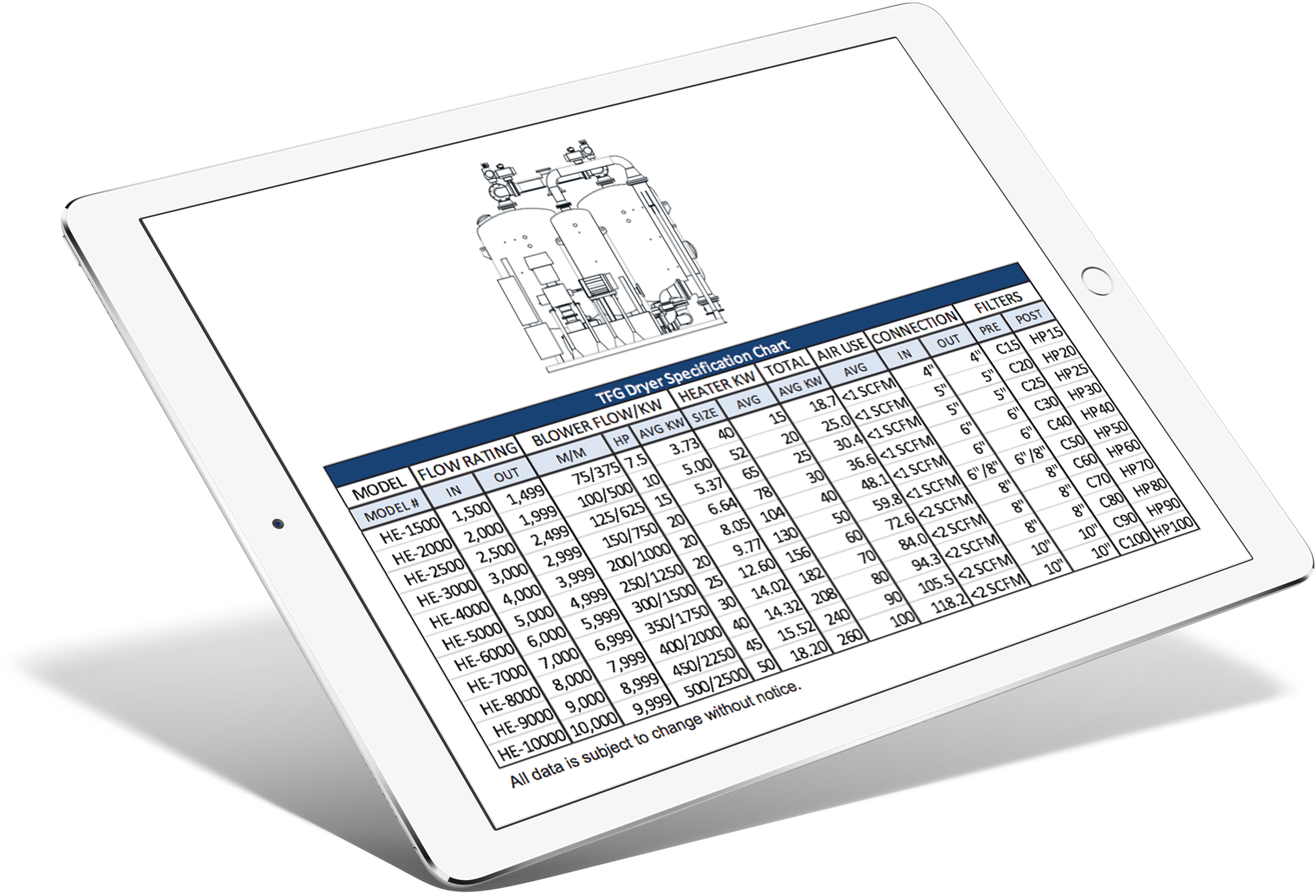

High Efficiency Blower Purge HE-HBP Series Dryers scale to meet your needs. For full product specification information packet please fill visit the contact page and one of our representatives will be contact.

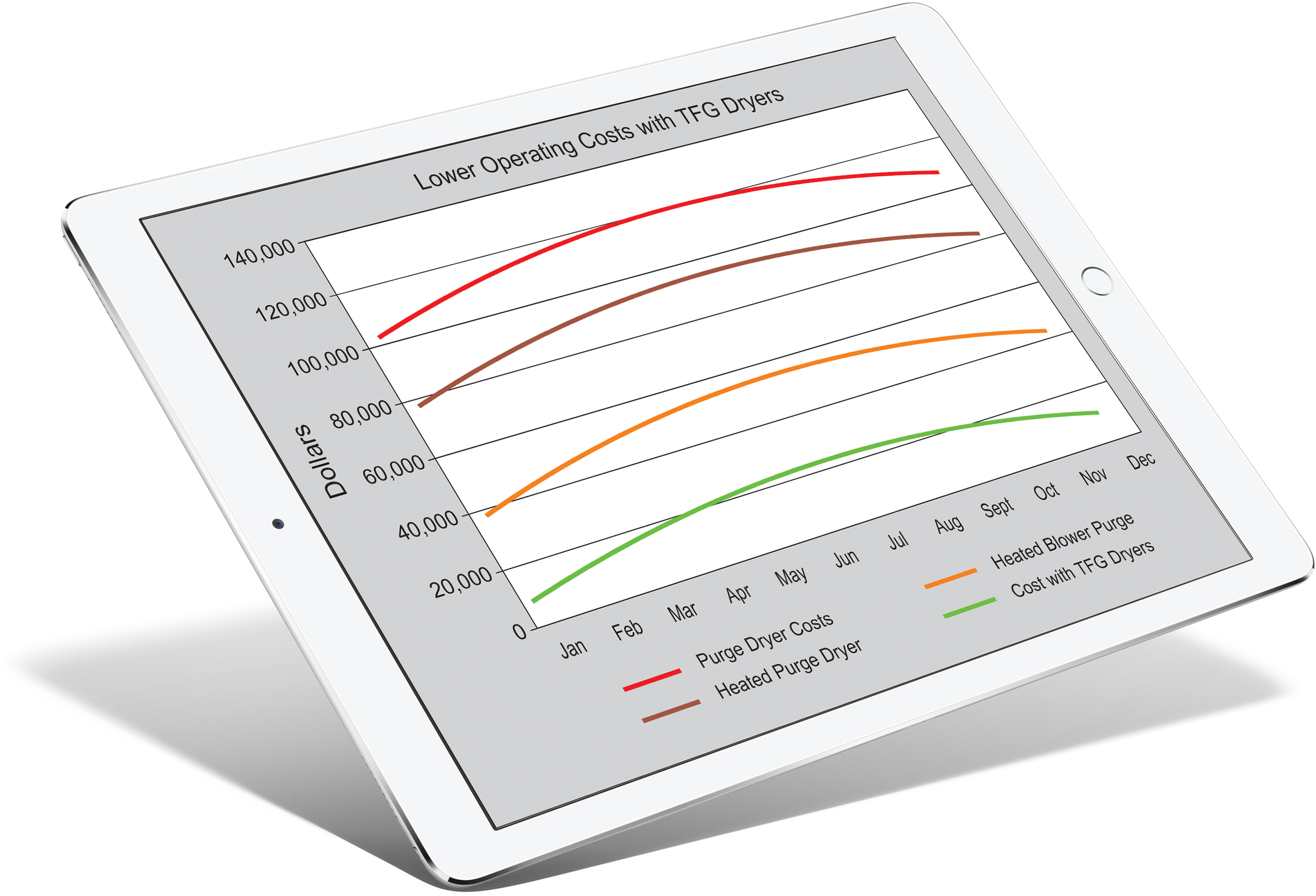

TFG Dryers are the smartest energy saving investments in the compressed air industry.

One steel processing plant stopped wasting 3,784 SCFM of plant air after making this change, and they consequently recouped nearly half a million dollars annually, lowering the total cost of operation from $1.15 million dollars to $750,000. They achieved full return-on-investment in just 24 months.

TFG Bone Dry Dryers and TFG Dryer Controls work together to save energy dollars.

| Simple | User friendly interface and touchscreen display with remote or local programming and control. |

| Analytics | System includes enhanced screens with real-time logging and trending. |

| Smart | Variable frequency drives respond to ambient conditions to save energy and money. |

| Flexible | Easily integrated into all SCADA systems and data historians using multiple PLC brands and platforms. |

Eliminating the use of plant air is a huge savings.

Eliminating the use of plant air will save hundreds of thousands of dollars annually. A desiccant dryer design that uses a third tank to dry atmospheric air represents a larger investment initially, but the energy savings from the efficiency gains typically generates a full return-on-investment after about a year of usage.

*Rebates from Electrical Utilities can dramatically increase the R.O.I. on a TFG Dryer.

For a brief period, air flows from the compressors through both tanks, while the purge air tank is prepped for service.

When the in-service tank needs to be regenerated, it is isolated from the compressed air system and hot purge air flows through the tank being regenerated so to sufficiently dry the desiccant, while protecting it from outside contaminants.

When the regenerating tank is moisture free, it goes into a cool down period, so that it is ready to take on the plant load.